Warehouse Energy Efficiency Starts with Sky-Walker

The Hidden Cost of Leaving Lights On

Energy efficiency is becoming one of the defining challenges in modern warehousing. Rising electricity costs, sustainability targets, and operational complexity are pushing logistics facilities to rethink how energy is used.

A strong starting point is lighting.

According to research highlighted in Utility Design's article, unnecessary lighting results in massive energy waste. Their study revealed that 10% of people regularly leave lights on when leaving a room, which results in approximately £14,950,000 (€17,450,000) of wasted energy every single day in the UK.

Even more striking, this behavior generates around 37,440,000 kg of CO₂ emissions per day, equivalent to 62 flights around the world.

When lights are left on during work hours, the impact becomes equally serious. About 21% of people admit to leaving lights on when leaving the house, wasting roughly £10,780,000 (€12,580,000) daily and producing 26,880,000 kg of CO₂ emissions, the equivalent of 45 global flights.

On an individual level, leaving lights on can cost:

- £2.30 (€2.70) per day

- £64 (€75) per month

- Over £800 (€935) per year

While these numbers already seem significant in homes, the implications in warehouses are far greater. Large logistics facilities operate with hundreds of lighting points across wide areas and extended operating hours. Even small inefficiencies multiply into serious operational costs.

But the problem is rarely human forgetfulness alone. In most cases, it is a systems issue.

Reference:

https://www.utilitydesign.co.uk/blog/leaving-lights-on/

The Real Challenge: Complexity

Warehouses are complex environments where lighting, heating, ventilation, access control, and security systems all operate simultaneously. These systems often function independently, without communication or coordination.

As a result, lights stay on in unused zones, heating or cooling runs in empty spaces, and energy consumption spikes without explanation.

Lighting alone can represent a major portion of total energy usage, especially in high-bay environments where illumination must cover large vertical and horizontal areas. When these lights operate unnecessarily, they not only consume electricity but also generate heat, which increases cooling demand.

This is where integration becomes essential.

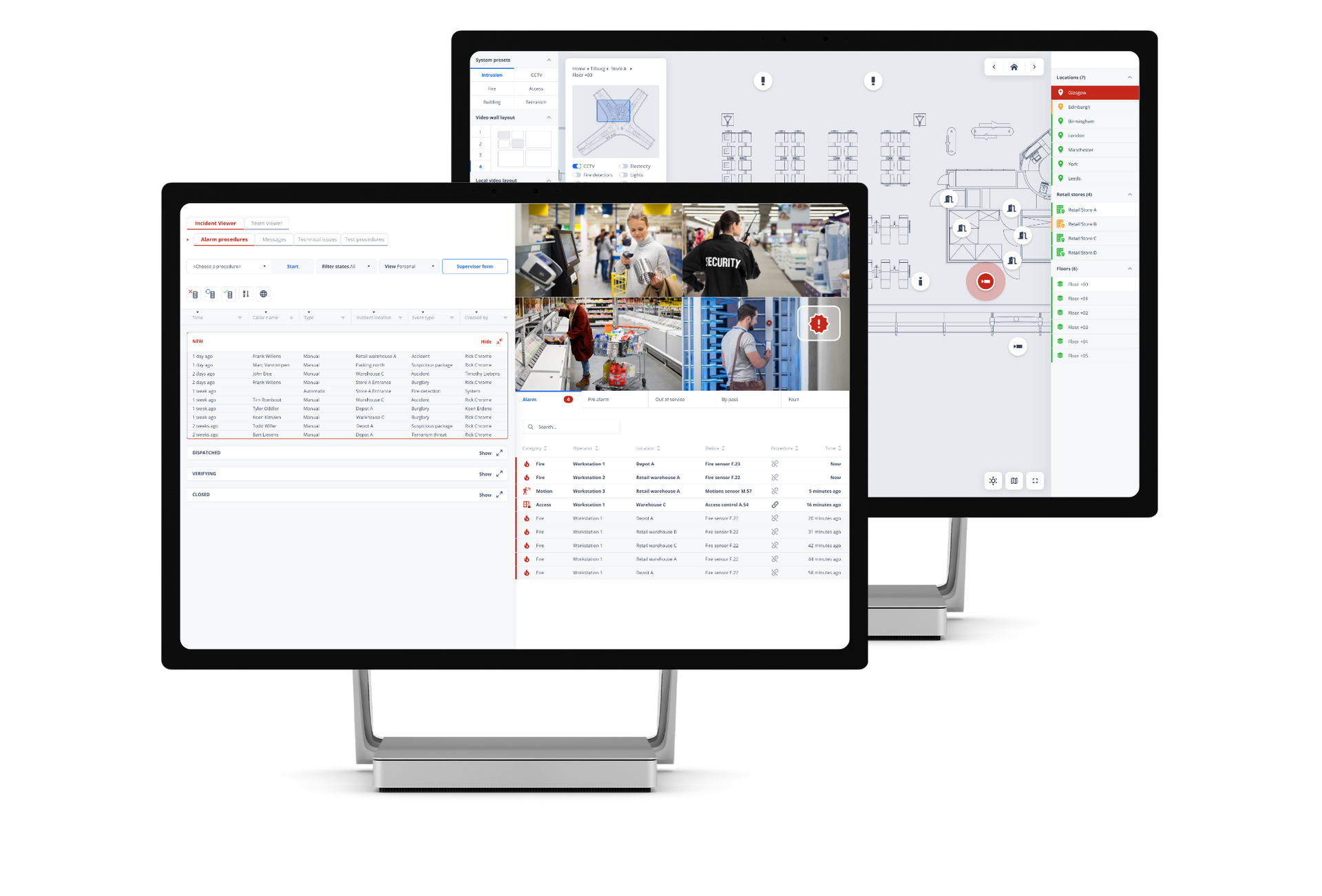

Lighting Systems Integration

Lighting systems are no longer just about turning lights on and off. Modern systems adjust brightness, respond to occupancy, and communicate operational status.

Through integration, lighting data is transmitted to a central platform where it can be monitored, analyzed, and optimized.

Instead of relying on manual checks, facilities gain the ability to monitor lighting status in real time, adjust intensity automatically, generate performance data, and reduce energy waste.

With an integration platform like Sky-Walker, lighting across multiple buildings or sites can be managed from one interface. This eliminates the common issue of lights remaining active overnight or in unused areas.

Energy Systems and Data Visibility

Energy efficiency improves dramatically when consumption is measurable.

Energy systems track electricity usage in real time, often in half-hour intervals. This allows organizations to understand where energy is being consumed and when.

Sky-Walker integrates these systems into one platform, enabling operators to monitor overall consumption and detect unusual spikes.

If lighting begins using excessive power, the system can notify operators instantly. Instead of discovering inefficiencies weeks later through invoices, action can be taken immediately.

Temperature Control and Worker Comfort

Energy efficiency is not only about reducing consumption, but it must also support a productive working environment.

Lighting and temperature are closely connected.

Traditional lighting systems produce heat, which can increase indoor temperatures and create discomfort. This additional heat forces HVAC systems to work harder, raising energy consumption even further.

In warehouse environments, this can lead to overheated picking zones, cold loading docks, or uneven temperature distribution.

By integrating lighting with HVAC systems through Sky-Walker, facilities can maintain stable and comfortable working conditions. If a door remains open for too long, lighting and temperature settings can adjust automatically. If an area becomes inactive, heating or cooling can be reduced accordingly.

This ensures workers operate in environments that are both energy efficient and comfortable, supporting productivity and safety.

Smart Automation Across Systems

The real advantage of integration lies in system collaboration.

Lighting does not operate in isolation. When connected with access control, energy meters, HVAC systems, and security systems, the facility begins to function intelligently:

- If no movement is detected, the lighting dims or shuts off.

- If energy usage rises unexpectedly, operators receive alerts.

- If occupancy increases, lighting and temperature adjust automatically.

Sky-Walker connects all these subsystems through one unified interface, allowing decisions to be made instantly rather than reactively.

Conclusion

The figures from Utility Design show how something as simple as leaving lights on can waste millions of pounds — or tens of millions of euros — and generate massive emissions daily.

If this level of waste occurs in homes, the potential impact in warehouses is exponentially larger.

Energy efficiency in logistics environments cannot rely on manual actions alone. It requires system intelligence, integration, and real-time visibility.

By combining lighting, energy monitoring, and temperature control into one platform, Sky-Walker transforms warehouse operations from reactive to proactive.

The result is not only reduced energy consumption and lower costs, but also improved worker comfort and smarter facility management.

In modern warehousing, efficiency is no longer about switching things off — it is about making sure systems work together intelligently.

Download Product Ebook

Download Product Ebook View all our solutions

View all our solutions Sky-Walker Architecture

Sky-Walker Architecture View all our integrations

View all our integrations Book Protocol workshop

Book Protocol workshop Our Company

Our Company Contact Us

Contact Us View All Our Case Studies

View All Our Case Studies Become a PSIM Partner

Become a PSIM Partner Become a Sky-Walker PSIM partner today!

Become a Sky-Walker PSIM partner today! English

English Français

Français Nederlands

Nederlands